ExT™ Lateral Solutions

Streamlined Deployment in Challenging Wellbores

ExT™ Wireline Cable System

Dramatically reduces cable friction, enables deployment of tool strings in difficult wellbores, and allows higher running speeds without the common torque issues that standard cables suffer.

• Faster run speeds

• Average of fourteen minutes to rig up PCE

• 25-50% decrease in friction

• Deployment in longer laterals

• Eliminates grease injection

• Eliminates grease head issues

• Prevents drum crush

• Higher strength to weight ratio

Ballistic Release Tool

• Improved compact design

• Higher bending momentum

• Compatible with multiple detonator/switch systems

• Increase in operational safety

• Increase in overall reliability

• Reduce unintentional surface release and failures downhole

• Eliminates becoming hydrostatically stuck downhole

• Strict quality control process

• Eliminates internal damage due to torque through tool

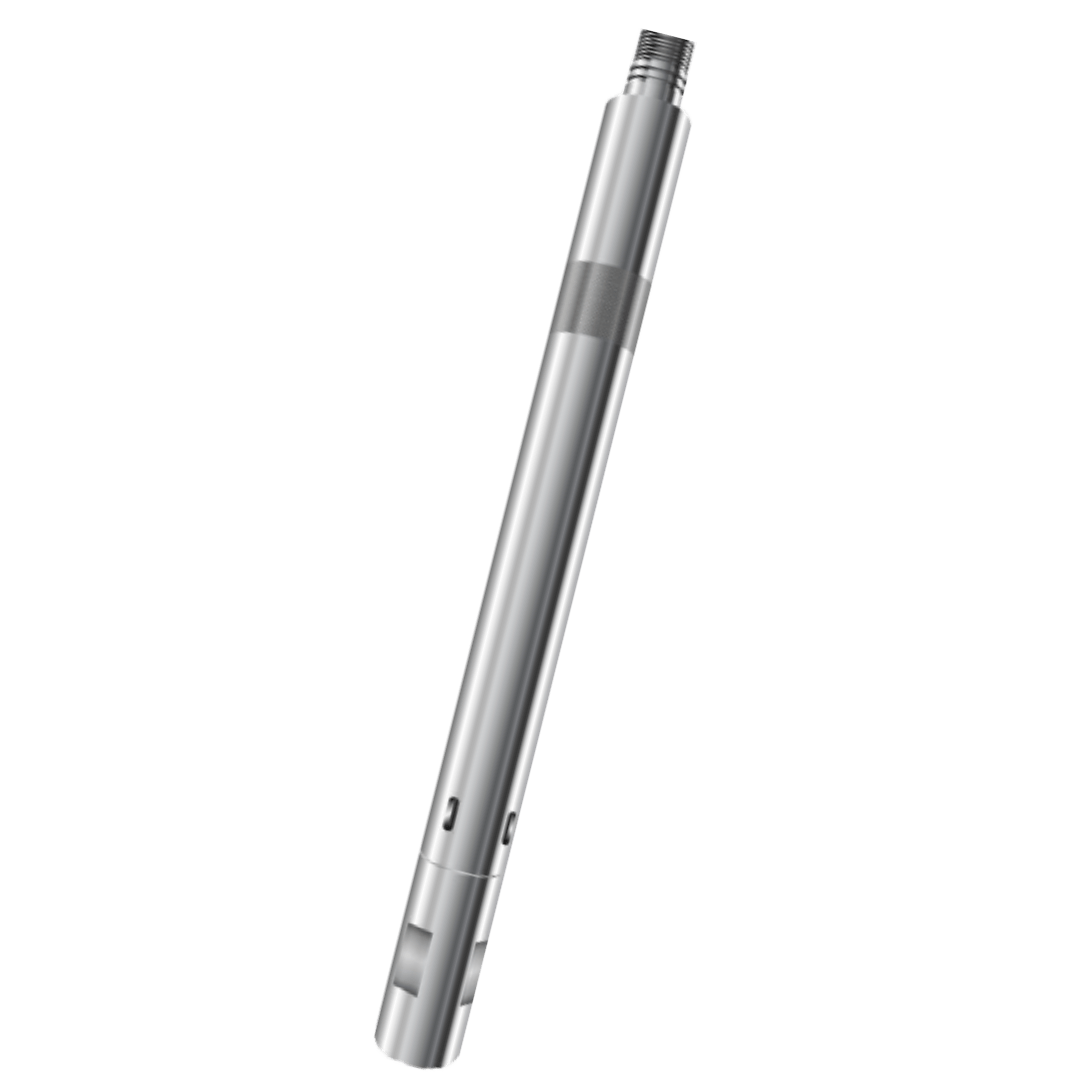

ExT™ Downhole Tension Tool

Specifically designed to reduce the risk of fishing operations during pump-down in extended lateral wells.

Prevent Pump-Off, Stuck Tools and Expensive Fishing Operations

• Minimizes fishing risk

• Compatible with commercial perforating systems

• Compact, low maintenance design

• No field calibration necessary

• Operates up to 350°F and 20k psi

Risk Deployment Models

Our modeling software can accurately predict and analyze cumulative forces at each stage of the wireline job.

Allows for effective pre-job planning

• Recommendation on risk mitigation options

• Confirm that target depth can be reached

• Determine if job can be performed at depth

• Ensure equipment can be safely returned to surface

• Post-job analysis to determine friction co-efficient