Automated Technology Systems

Revolutionizing Well Operations with Innovative Solutions

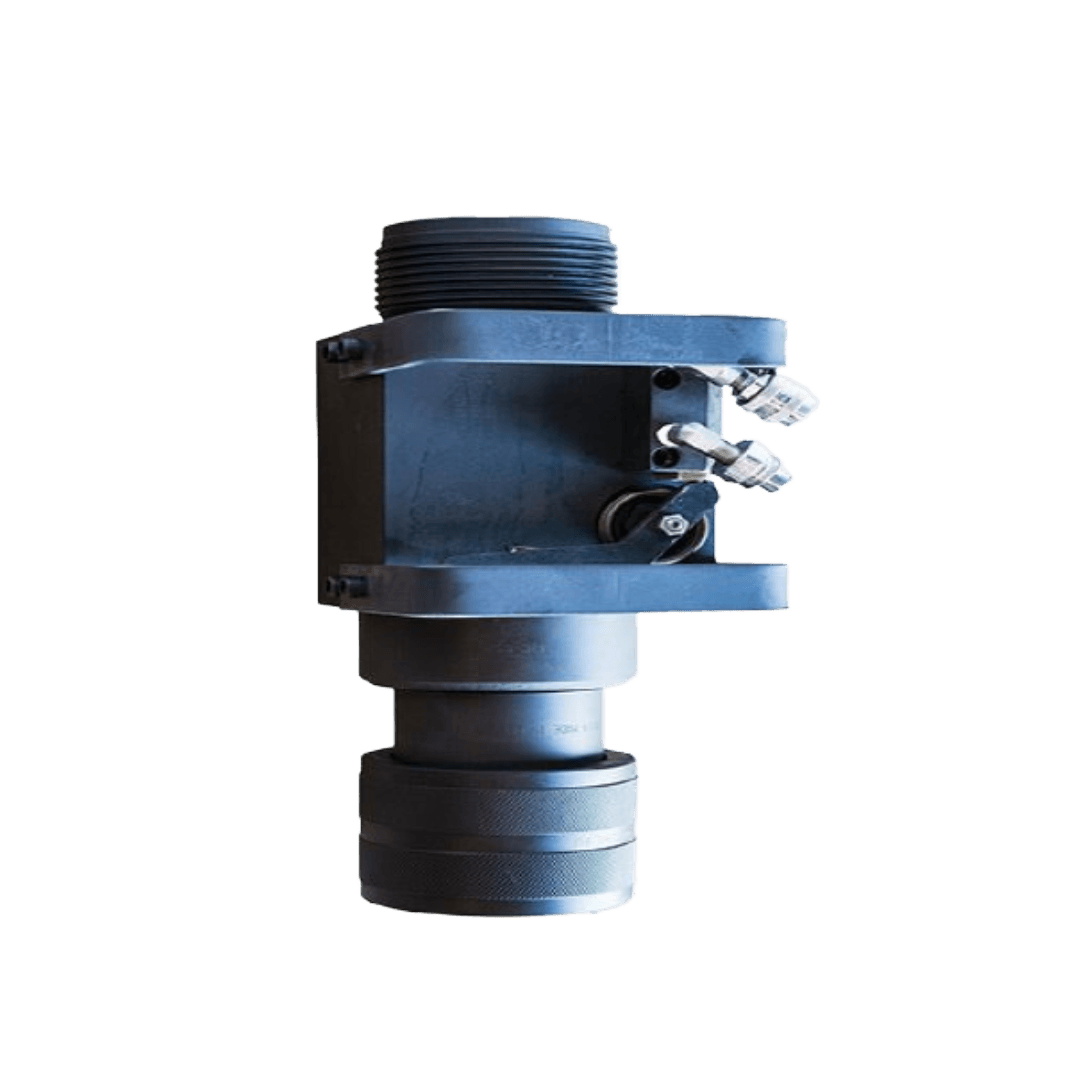

Automated SEER Packoff

• Eliminates all common failure points found in current designs

• Improves efficiency by addressing over 80% of coated cable incidents

• Injection-less system with no free-floating brass bushings

• Handles working pressures up to 12,500 PSI

• Designed with 3 velocity check valves for operational safety

• Increases equipment longevity and supports 200+ runs before redress

• Integrated transducer system for accurate pressure detection

SecureTrap Systems

The SecureTrap System enhances tool trap operations by combining advanced monitoring, precise measurements, and design improvements to ensure reliable, efficient, and safe performance

• Eliminates all common failure points found in current designs

• Improves efficiency by addressing over 80% of coated cable incidents

• Injection-less system with no free-floating brass bushings

• Handles working pressures up to 12,500 PSI

• Designed with 3 velocity check valves for operational safety

• Increases equipment longevity and supports 200+ runs before redress

• Integrated transducer system for accurate pressure detection

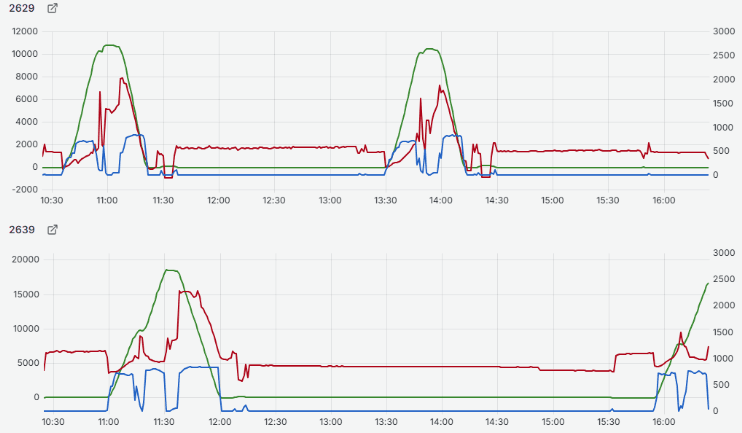

Horizontal Visualization System

• Provides access to historical data for diagnostics and analysis.

• Simplifies troubleshooting by tracking Key Performance Indicators

• Transforms complex data into actionable insights

• Customizable dashboards enable quick identification of issues

• Monitors performance across teams and processes

• Promotes standardization across workflows

• Helps drive efficiency and continuous improvement in operations

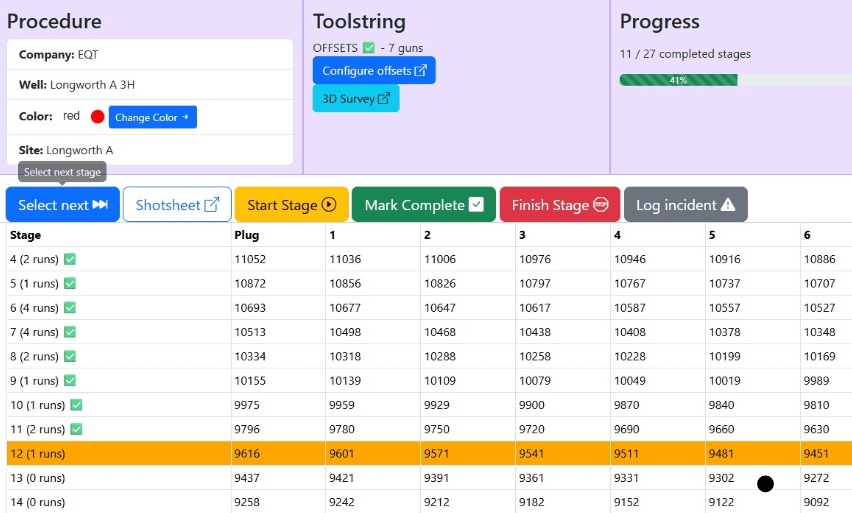

Procedure Integration Managment System (P.I.M.S.)

• Ensures consistent adherence to procedures across all operation

• Seamlessly integrates job procedures for accurate process execution

• Uploads and utilizes job procedures for auto-stop depth

• Significantly reduces error and misinterpretation in procedures

• Increase in overall reliability and efficiency

• Promotes standardization across workflows

• Allows customers to access real-time updates

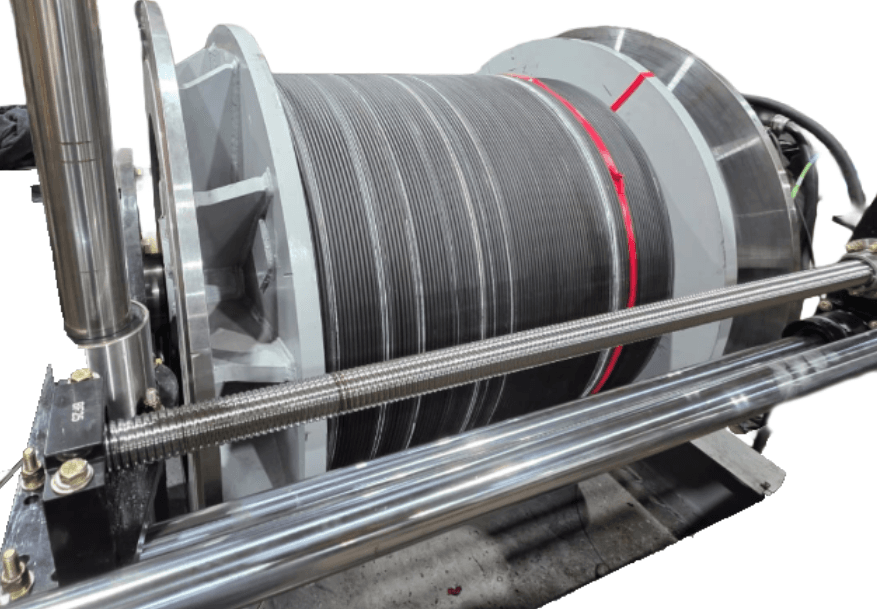

Safe Winch System

• Ensures correct spooling of wireline cable

• Monitors and corrects miswraps in real time

• Tracks total cable depth for precise operations

• Automates winch positioning to predefined safe depths

• Reduces manual intervention and operator error

• Promotes standardization across workflows

• Supports predictive maintenance by monitoring cable usage and wear

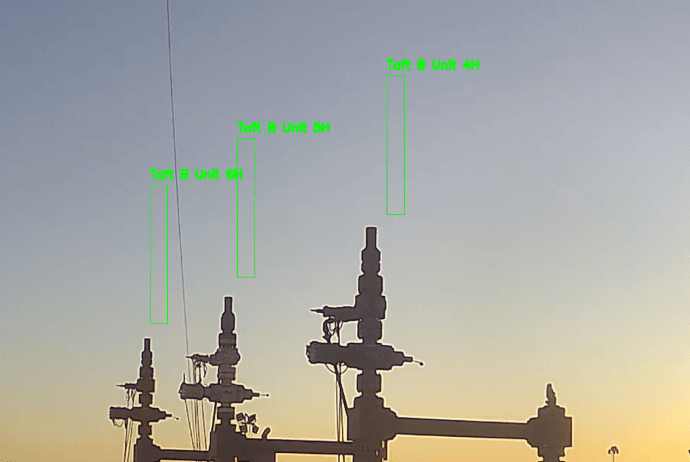

WellScope Identifier

Horizontal Wireline's WellScope Identifier is designed to bring automation to well identification to mitigate human error.

• Drastically reduces operation errors

• Real-time camera feedback

• Measures drum position during bump-up

• Automates well identification

• Reduces manual intervention and operator error